Zinc Clip-on Weight for Steel Rims

XG-06C

Item | Description |

Part. No. | XL-07C(Uncoated XG-07) |

Material | Zinc |

Size in GR | 5g, 10g, 15g, 20g, 25g, 30g, 35g, 40g, 45g, 50g, 55g, 60g |

Model | Clip-on/hammered/nail/knock-on |

Finish | Plastic coated |

Application | Passenger cars alloy rims |

Technics | Die-casting |

Box quantity | 5-30g 100pcs/box 35-60g 50pcs/box |

Important features:

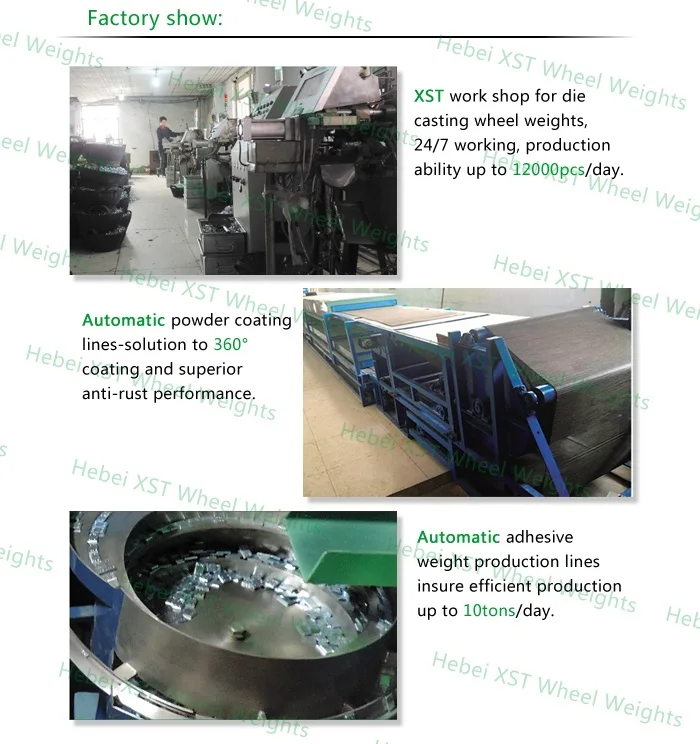

1. Professional balance weight MANUFACTURER

2. Strong and good quality clip

3. Cam-back design for good retention

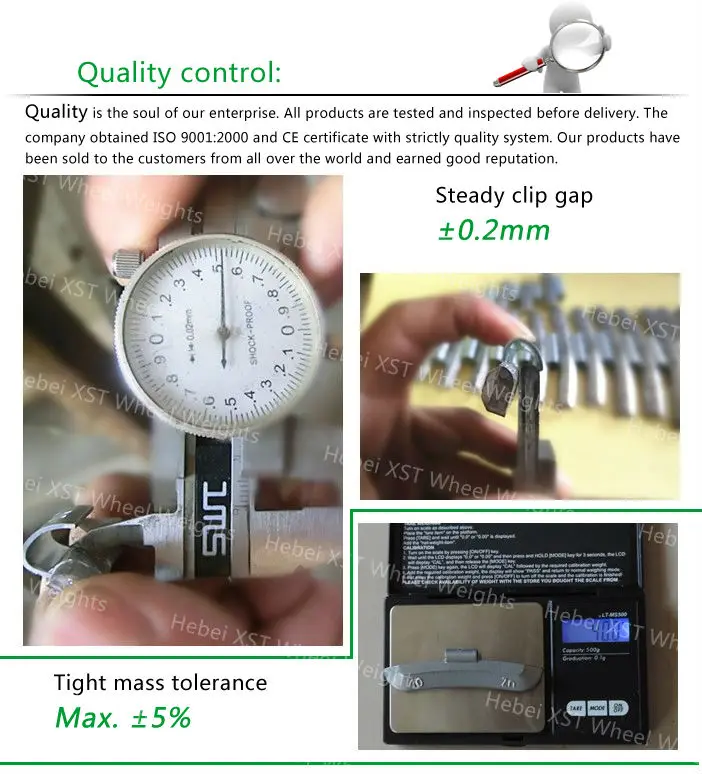

4. Tight mass tolerance, accurate clip gap

5. RoHS directive compliance. Lead free, environmental friendly.

6. ISO9001:2000 quality management system certification.

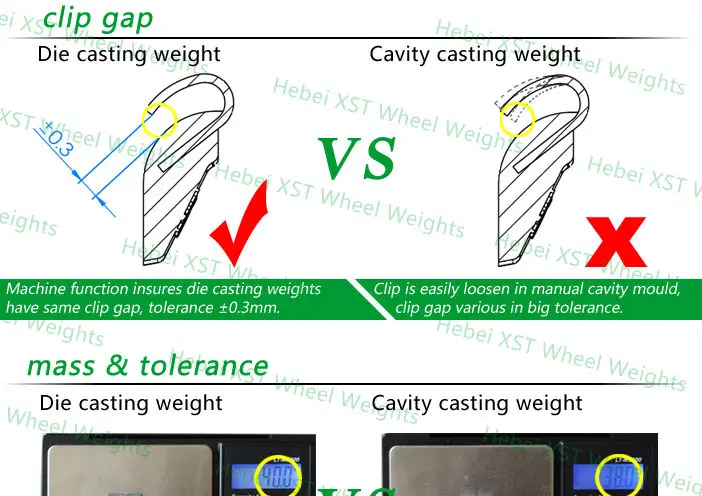

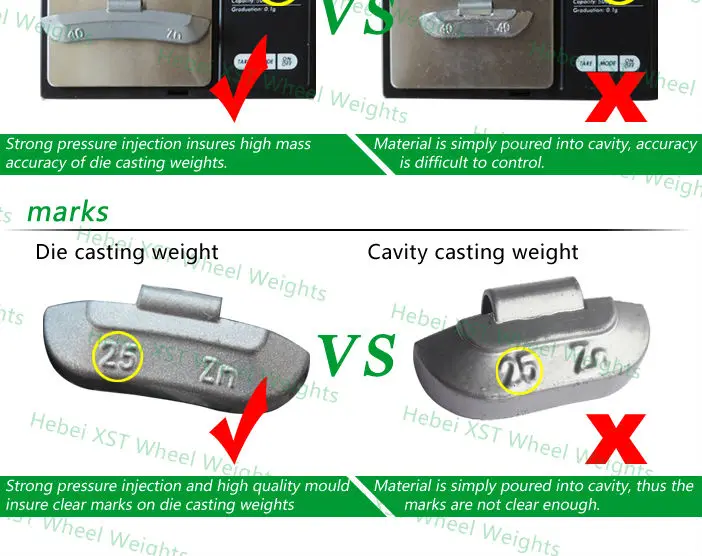

There are 2 production methods for zinc and lead weights, die casting by machine and cavity casting by manual. XST has developed machines for die casting weights. What are the good aspects of die casting weights? Why a lot of customers like die casting weights?

Following compare shows obvious differences between the die casting weights and cavity casting weights:

Our service\Buyer Guidelines: