Features

1.It provides superior oil resistance, heat resistance and aging resistance by using special synthetic rubber.

2.It provides high pressure resistance and superior impulse resistance.

3.It provides superior bonding in hose internal, soft use and small deformation under pressure.

4.It provides superior kink resistance and fatigue resistance and longer services life.

Application

Mainly used in mine hydraulic support, oil exploration, suitable to engineer construction, crane transport, forging metallurgy, mining equipment, ships, injection molding machinery, agricultural machinery various machine tools.

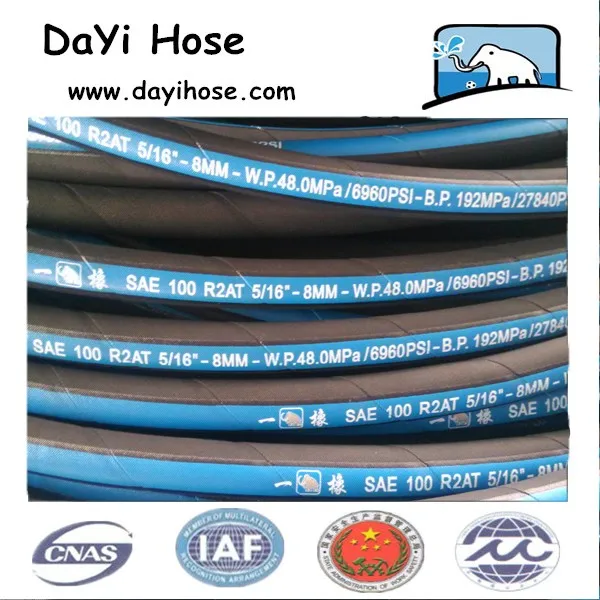

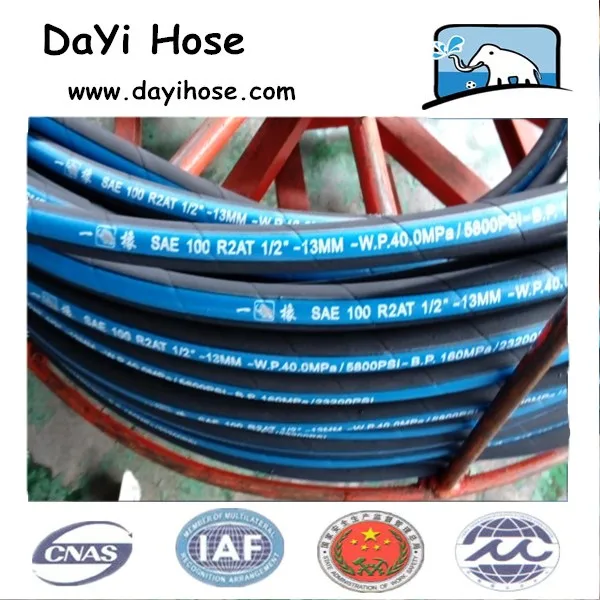

RUBBER HOSE /HYDRAULIC HOSE SAE 100 R2 AT / DIN EN 853 2SN

CONSTRUCTION: This hose consists of an inner tube of oil synthetic rubber, two wire braids reinforcement, and an oil and weather resistant synthetic rubber cover.

APPLICATIONS : Hose range suitable to carry hydraulic fluids such as glycol, mineral oils,fuels,lubrication,emulsion,hydrocarbons etc. WORKING TEMPERATURE

From-40 degree up to +100 degree

| Nominal | Inside | Reinforcement | Outside | Working | Proof | Burst | Min.Bend | Weight | ||||

| diameter | Diameter | Diameter | Diameter | Pressure | Pressure | Pressure | Radius | Kg/m | ||||

| mm | mm | mm | MPa | MPa | MPa | mm | ||||||

| mm | inch | min | max | min | max | max | max | PSI | min | |||

| 4.8 | 3/16" | 4.6 | 5.4 | 10.6 | 11.7 | 14.1 | 34.5 | 5003 | 68.9 | 138 | 100 | 0.3 |

| 6.4 | 1/4" | 6.2 | 7 | 12.5 | 13.1 | 15.2 | 34.5 | 5003 | 69 | 138 | 100 | 0.3 |

| 7.9 | 5/16" | 7.7 | 8.5 | 14.2 | 14.8 | 17.1 | 29.3 | 4249 | 58.6 | 117 | 115 | 0.36 |

| 9.5 | 3/8" | 9.3 | 10.1 | 16.2 | 16.8 | 19.1 | 27.6 | 4002 | 55.2 | 110 | 130 | 0.49 |

| 12.7 | 1/2" | 12.3 | 13.5 | 19.4 | 20 | 22.3 | 24.1 | 3495 | 48.3 | 96.5 | 180 | 0.56 |

| 15.9 | 5/8" | 15.5 | 16.7 | 22.8 | 23.4 | 25.8 | 19 | 2755 | 38 | 76 | 200 | 0.6 |

| 19 | 3/4" | 18.6 | 19.8 | 26.4 | 27.2 | 29.4 | 15.5 | 2248 | 31 | 62 | 240 | 0.83 |

| 25.4 | 1" | 25 | 26.4 | 33.9 | 34.7 | 37.1 | 13.8 | 2001 | 27.6 | 55.2 | 300 | 1.22 |

| 31.8 | 1-1/4" | 31.4 | 33 | 42.8 | 43.6 | 46.1 | 11.2 | 1624 | 22.4 | 44.8 | 420 | 1.91 |

| 38.1 | 1-1/2" | 37.7 | 39.3 | 49.2 | 50 | 52.5 | 8.6 | 1247 | 17.2 | 34.5 | 500 | 2.17 |

| 50.8 | 2" | 50.4 | 52 | 61.9 | 62.7 | 65.2 | 7.8 | 1131 | 15.5 | 31 | 630 | 2.74 |

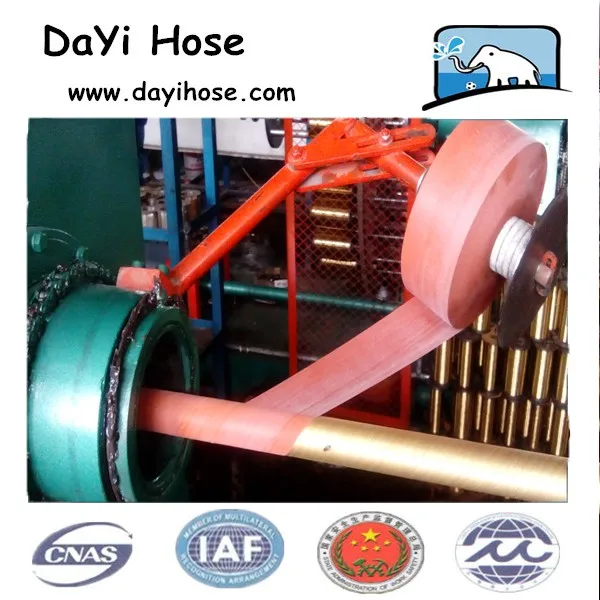

We are the leading manufacture specialized in designing and manufacturing different kinds of hydraulic & high-pressure rubber hose in China with experience of more than 10 years,possessing the ISO 9001 certification.We help customers develop special and quality hydraulic rubber hose for according to the needs .

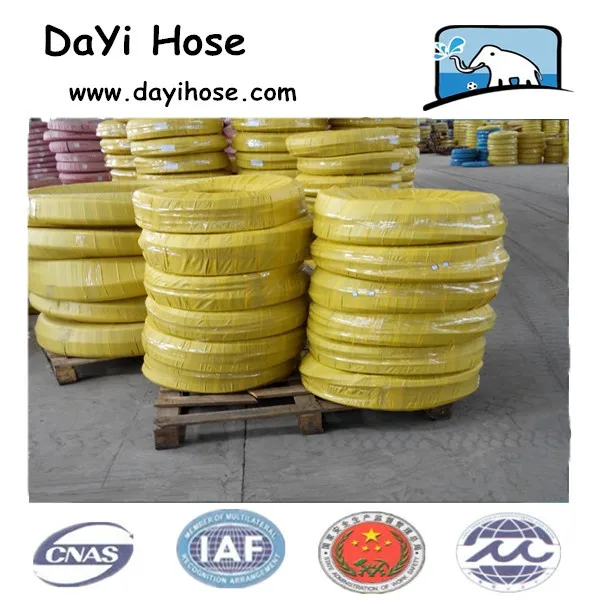

The general package of hydraulic hose is plastic or woven bag with pallet under the hose, which can be seen below. We, however, can also provide special package according to customer’s requests.

RUBBER HOSE/ HYDRAULIC HOSE - HEBEI DAYI RUBBER HOSE CO.,LTD

We can offer OEM Services

We can provide FREE SAMPPLE for our customers

We can crimp hose assembly for our customers.

We welcome clients to visit our factory leading to better understanding of our production.

Q1. Do you produce smooth or cloth wrapped cover?

A. Both, we can produce both cover, which depends on customer’s request.

Q2. Do you produce embossed marking?

A. Yes, we do provide embossed and printing markings with different color.

Q3. Can you produce product with my own brand?

A. Yes, we have been offering OEM services for 20 years.

Q4. Does your product have different color hose?

A. Yes, we currently provide black, grey, red, blue and yellow.

Q5. How long does my order take to be delivered?

A. It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

Contact WITH Ella: